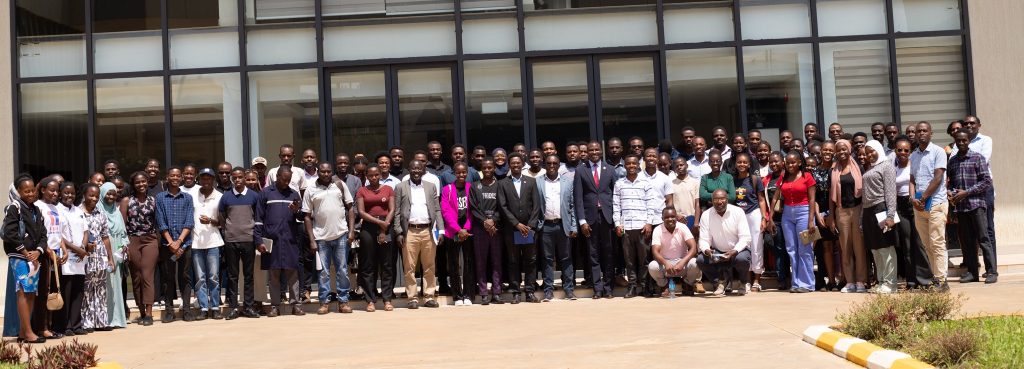

Makerere University School of Engineering, in collaboration with UNESCO CFIT III under the Precision Engineering, Skilling, Innovation, and Commercialization (PESIC) framework, recently facilitated a series of impactful industry visits. This initiative brought together students, faculty, and researchers from across the university, including Makerere University College of Computing & Information Science (MaK CoCIS), Biomedical Engineering under Makerere University College of Health Sciences School of Medicine(CHS), and the School of Food Science, Nutrition and Bioengineering(CAES).

The objective of these strategically curated tours was to foster meaningful industry engagement and collaboration, effectively bridging the theoretical foundations of academia with practical industry applications. Participants gained invaluable insights into advanced manufacturing processes, innovation ecosystems, and entrepreneurial strategies. A significant emphasis was placed on understanding the pathway to commercialization, equipping participants with the knowledge and access to resources necessary to transition prototypes into market-ready products and minimum viable products (MVPs).

Key focus areas of these visits included refining innovations, acquiring industry-aligned expertise in domains such as advanced manufacturing and hardware-software integration, and establishing viable commercialization routes. The visits encompassed the following prominent innovation hubs:

DeepTech Center of Excellence and Uganda Industrial Research Institute (Namanve Industrial Park)

National Innovation Hub, UICT Augumented and Virtual Reality Lab, and Uganda Communications Commission Testbed (Nakawa UICT campus, Kampala)

National Science, Technology, Engineering, and Innovation Skills Enhancement Project (NSTEIC) Engineering Development and Innovation Center (Rwebitete, Kiruhura District)

This initiative underscores Makerere University’s commitment to fostering innovation, enhancing the practical skills of its stakeholders, and driving the development of commercially viable, locally manufactured solutions. We look forward to witnessing the translation of these experiences into impactful outcomes